Thermal Treatments

Below are excerpts taken from EPA publication: Guide to In Situ Thermal Treatment

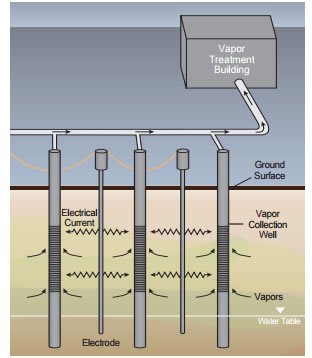

In situ thermal treatment methods mobilize and evaporate contaminants in soil and groundwater using heat. The chemicals move through soil and groundwater toward wells where they are collected and piped to the ground surface to be treated using other cleanup methods. Some chemicals are destroyed underground during the heating process.

Volatile organic compounds (VOCs) such as solvents and gasoline evaporate easily when heated. Thermal technologies can be very effective on some of the heavier compounds that require higher temperatures to evaporate, including semi volatile organic compounds (SVOCs), diesel fuel, creosote (a wood preservative), coal tar, and several pesticides. Thermal processes can be particularly effective on non-aqueous phase liquids (NAPL), which do not dissolve readily in groundwater and can be a source of groundwater contamination for if not treated (e.g., solvents, petroleum, and creosote).

Thermal treatment may take from a few weeks to a few years. Thermal desorption may be faster at reaching cleanup goals than other methods, particularly at sites that have high concentrations of contaminants. The actual cleanup time will depend on several factors. For example, thermal treatment may take longer where:

- Contaminant concentrations are high.

- The contaminated area is extensive or deep.

- A variety of soil types are present, causing the ground to heat unevenly.

- The soil has a lot of organic matter, which causes chemicals to stick to the soil and tend to not evaporate.

Thermal methods generate heat in different ways:

- Electrical resistance heating (ERH) delivers an electrical current between metal rods (electrodes) installed underground.

- Steam enhanced extraction (SEE) injects steam underground by pumping it through wells drilled in the contaminated area.

- Thermal conduction heating (TCH) uses heaters placed in underground steel pipes.

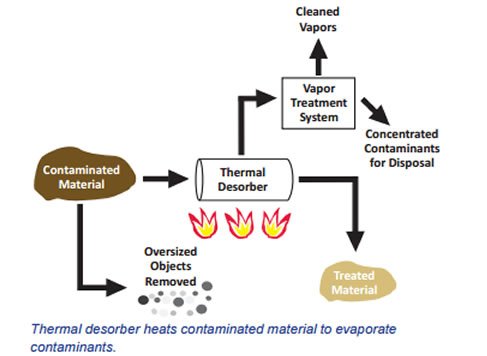

- Thermal desorption removes organic contaminants from soil, sludge or sediment by heating them in a thermal desorber. The desorber may be assembled onsite for treatment, or the material may be transported to an offsite thermal desorption facility. Low-temperature thermal desorption (200-600ºF) is used to to treat VOCs. If SVOCs are present, temperature requirements range from 600-1000ºF. Gas collection equipment captures the contaminated vapors. The vapors often require further treatment, using a thermal oxidizer, which heats the vapors to temperatures high enough to convert them to carbon dioxide and water vapor. At some sites with high concentrations of organic vapors, the vapors may be cooled and condensed to change them back to a liquid form. The liquid chemicals may be recycled for reuse, or treated by incineration. If the concentrations of contaminants are low enough the vapors may be released without treatment to the atmosphere.

Thermal treatment methods speed the cleanup of many types of chemicals, and are among the few technologies that can treat NAPL in situ. A faster cleanup may be important if a contaminated site poses a threat to the community or needs to be cleaned up quickly so that it can be reused. Thermal treatment can be used in silty or clayey soil where other cleanup methods do not perform well. Thermal can reach contamination deep underground or beneath buildings, which would otherwise be difficult or costly to dig up to treat above ground. Thermal desorption methods are typically only used to clean up soil that is contaminated at depths shallow enough to reach through excavation.