Air Sparging (AS) / Soil Vapor Extraction (SVE)

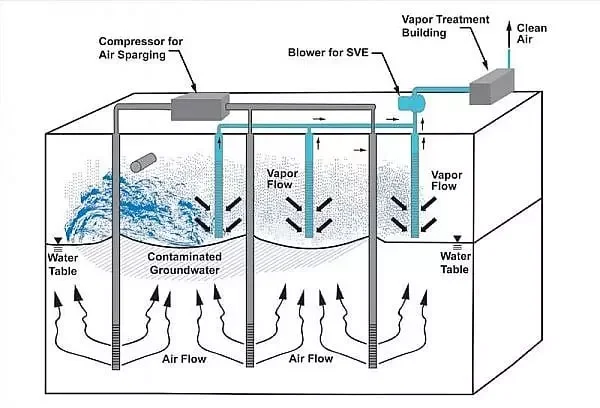

Air sparging (AS) is an in-situ remediation process that can be effective at removing volatile organic compounds (VOCs) from impacted media in the saturated zone (and because you need a soil vapor extraction [SVE] system to capture the vapors, also the vadose zone). VOCs can be liquids within the soil pores, solutes in groundwater, adsorbed onto soil particles, and/or vapor entrapped between soil particles.

Injection of air into groundwater (through AS wells) will partition and transport VOCs in vapor form into the vadose zone, where operation of SVE wells can provide a moving air-stream to capture and treat the impacted vapors. Without an SVE system, the vapors are likely to impact either vadose zone soils or potentially the indoor air of nearby structures.

An additional benefit of AS is that the injection of air will likely increase redox conditions in the groundwater, resulting in the potential for increasing the rate of bioremediation of petroleum compounds. Alternatively, an increase in redox conditions may temporarily prohibit the reductive dechlorination of chlorinated solvents in the saturated zone.

SVE is often used as a stand alone remedy when VOCs are only impacting unsaturated soils. By applying a vacuum to vadose zone wells, air is drawn down from the atmosphere and through the soil column, enhancing volatilization. The captured vapors are drawn to the surface for treatment and discharge, as required.

As a general rule, compounds with volatility (i.e., a vapor pressure of greater than 1 mm of mercury) are potential candidates for AS / SVE. Some compounds with high aqueous solubilities (e.g., 1,4-dioxane) may be difficult to remedy with these technologies. Additionally, metals may be precipitated via the geochemical changes induced by the injection of air into groundwater. The geochemical changes and metals precipitation may be a transient condition.

AS / SVE is a cost-effective remedial technology for removing VOCs. In general, the cost is less sensitive to the total mass of VOCs than other technologies, such as bioremediation or in situ chemical oxidation (ISCO). Additionally, AS / SVE systems can be installed and operated underneath buildings with minimal disruption. Lower permeability soils can reduce the cost effectiveness of these technologies.

Depending upon the design of the system, AS / SVE can take anywhere from one to more than three years. It is important to understand the site conceptual model relative to the magnitude of impacts when trying to set achievable goals.

Design considerations

- What are the contaminants and their properties?

- Where is the source?

- What is the site hydrogeology?

- Heterogeneous geology may result in preferential treatment of soils with high permeability, or poor treatment of soils with low permeability

- Can be negatively affected by highly variable groundwater table

Conceptual Modeling and Pilot Testing

- Modeling to determine pore-volume exchanges or soil gas velocities

- Injection / extraction rates

- Radius of influence of each well location (determines the number and spacing of wells)

- Estimation of timeframe to meet project goals

- General performance capabilities

Optimization

- Adjusting flows to target specific areas or depth intervals

- Varying injection / extraction rates and locations to prevent the system from shifting the contamination into unimpacted areas.